Corona Treaters for

Digital Print & Finishing

Surface treatment might be only an ancillary part of the overall production process, but it’s one of the most vital links in the chain if you are dealing with polymeric or foil substrates. Poor corona coverage will pose quality issues downstream, leading to increase production costs for the printer / convertor

Corona treaters for surface enhancement of a wide range of substrates are standard practise for several digital print & finishing lines whether you are coating, laminating, varnishing increased wetting of the substrate improves adhesion bond strengths resulting in a superior finish and end product. Even substrates that have been treated prior to delivery can cause issues if the surface tension / dyne level has decreased due to time, heat or humidity. This will prevent optimum running of your production process, increasing costs per metre run. By corona treating all substrates in-line, a one-off purchase, you can be confident of perfect results every time.

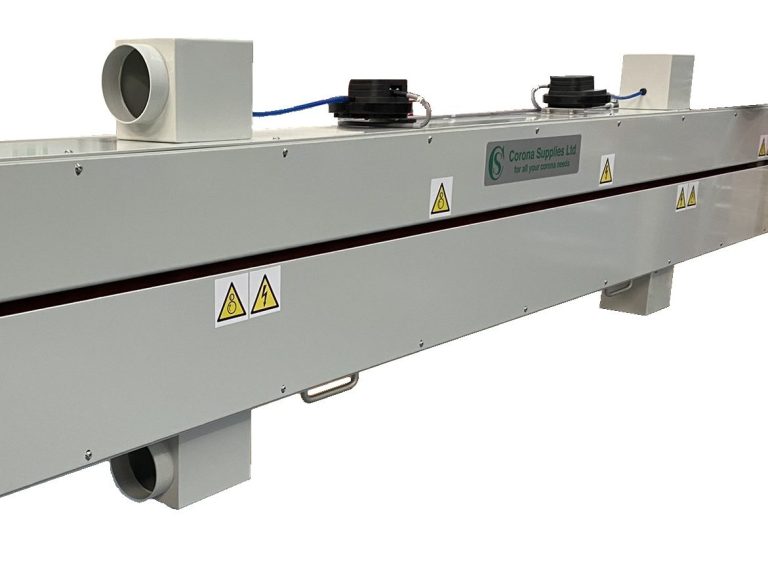

Narrow Web Corona Supplies manufacture compact yet powerful corona treaters for use in narrow web label print & finishing presses. Our corona treaters can be used to treat both conductive and non conductive films.

Corona Supplies cantilevered corona system is easily installed on all of the major presses. Our corona treaters have been installed on digital print & finishing presses from: Dantex Digital, Duplo, AB Graphic International, HP Indigo, Bobst, Xeikon etc.

- Cantilever design from single back-plate

- Uniform mounting to suit most types of press.

- Multiple Ceramic electrodes for good corona dwell

- Single, Double or Triple treat available

- Easy access for web threading and cleaning

- Film path rollers fitted as standard

- “Set and forget” air gap adjustment

- HT cable and ozone removal at back of treater for more ergonomic design

Wide Format digital printing is becoming more and more common with the majority of finished products being used outdoors. Corona treatment ensures the longevity and vibrancy of printed inks on materials subjected to all kinds of environmental conditions.

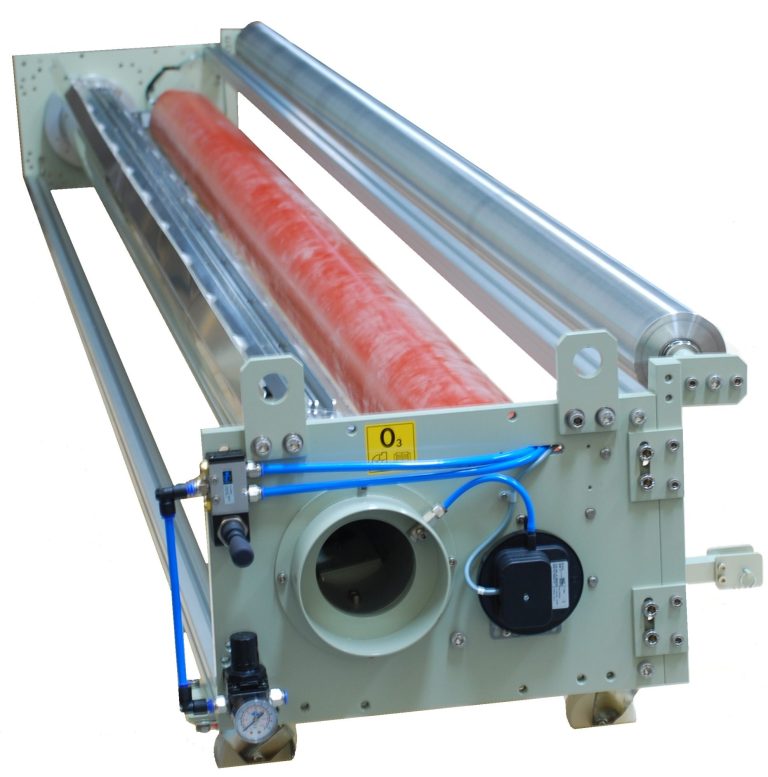

Corona Supplies manufacture corona systems to suit reel to reel, wide format printers up to 3.2 meters which can be supplied freestanding, allowing easy integration into most if not all printers on the market today.

- Free-standing or Integrated

- Widths up to 3200 mm and speeds up to 100 m/min

- Suitable for treating woven materials up to 3mm thick

- Suitable for "stop / start" web transport

- Easy to clean and maintain electrode cartridges, rotate 180 degrees without loss of HT connection.

- Easy, removable electrode cartridges

- Calibrated direct action, cross-web air gap adjustors for uniform treatment

Sheet Fed Corona Supplies have an "off the shelf" solution for corona treating sheets on digital print & finishing lines. Our standard design is based around the B1 size sheet allowing a throughput of up to 4000 sheets per hour.

It is important to note that the sheets must be travelling individually when they pass through the corona treater, to ensure the whole surface of the sheet is exposed to the corona discharge.

Custom design Corona Supplies offer customised solutions for the digital print & finishing market. From single sheets to high speed webs Corona Supplies can design a solution to suit your application.

©Copyright Corona Supplies Ltd. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.